The as-planned versus as-built schedule delay analysis compares events that actually took place during a project’s execution to events that were planned to take place prior to the performance of the work. The as-planned versus as-built schedule analysis is generally used globally on construction projects that are not complicated or are not scheduled using critical path methodology (CPM). GlassRatner has also encountered situations where this form of schedule analysis was required or is the best option due to available schedule and work progress data. In some cases, this approach can provide insight into whether a more detailed analysis is warranted.

The as-planned versus as-built analysis is a retrospective methodology that compares the contract schedule, or what is referred to as the baseline as-planned construction schedule, to the as-built schedule or contemporaneous progress documentation data and information. This technique can also utilize a schedule, or schedules, that reflect work activity progress through a particular point in time.

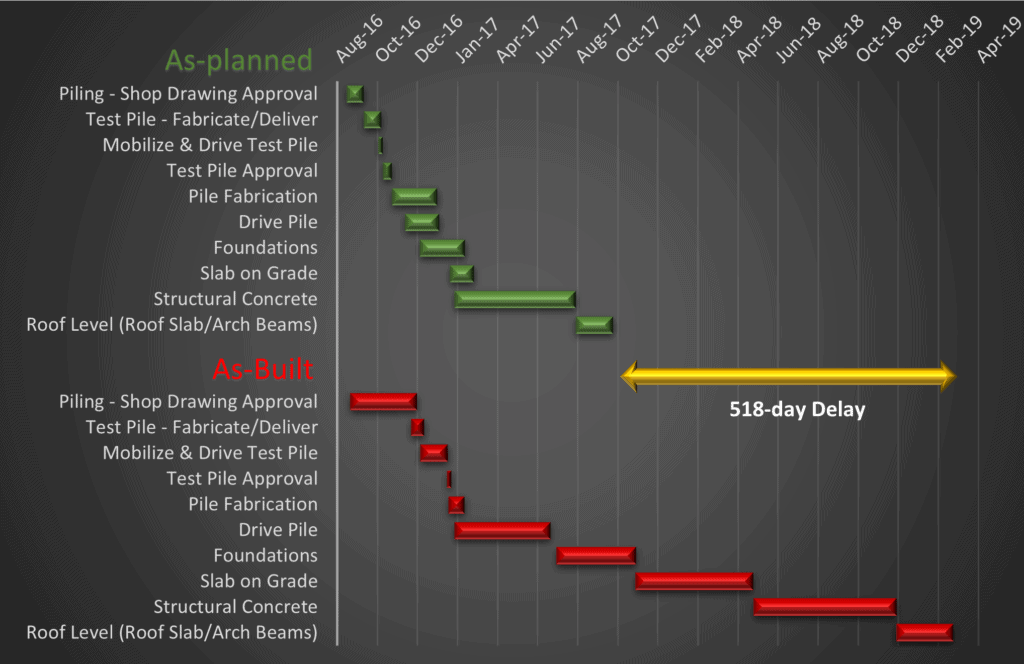

Implementation of the as-planned versus as-built schedule delay analysis can vary from a simple graphical comparison to a more sophisticated implementation and often uses bar charts for illustration. Even though a critical path for the construction project may not be specifically identified on the schedule, it could still be possible to model a critical path of both the as-planned and as-built schedules to identify delays to certain activities. As an example, linear construction projects, such as roads or overland pipeline and marine construction projects with discrete delay issues, may utilize the as-planned versus as-built schedule analysis method to identify delays and issues contributing to the delays. The graphic below shows the effects of delays in an as-planned (baseline) versus as-built schedule analysis.

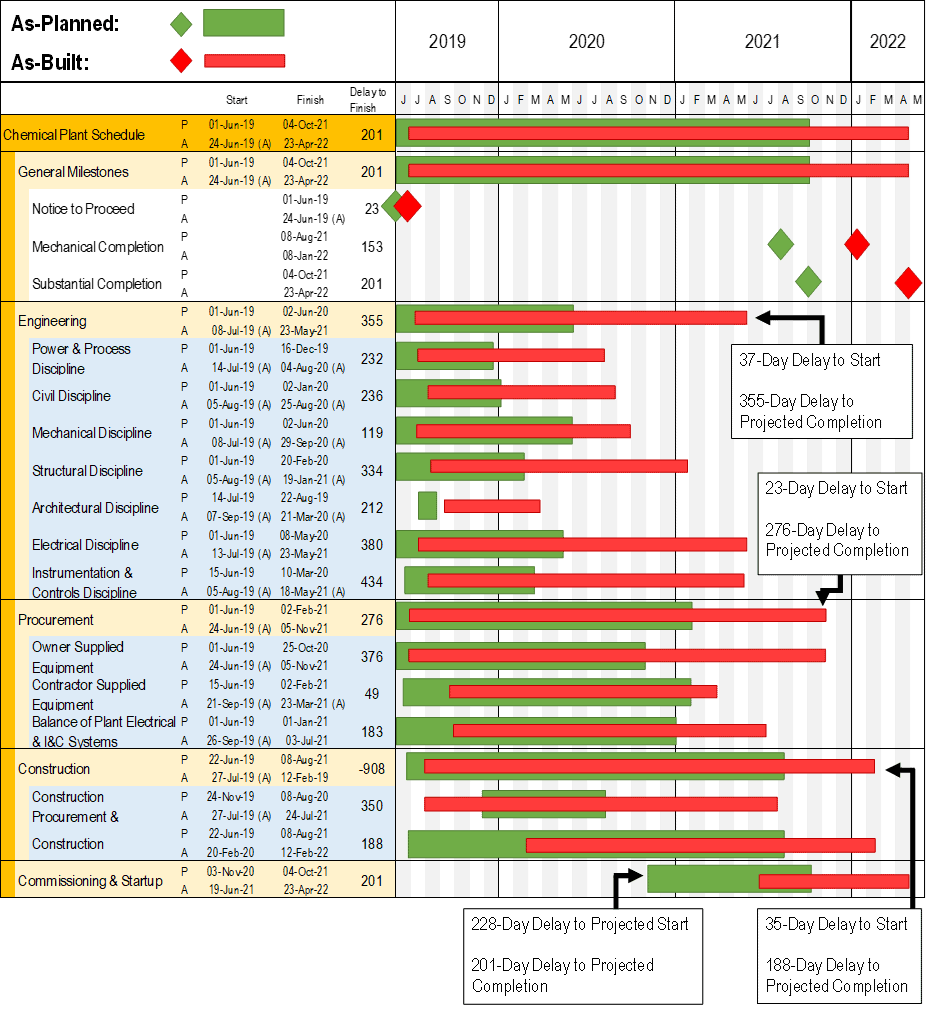

A more sophisticated implementation of the as-planned versus as-built schedule analysis methodology can be performed if detailed schedule information is available. For example, comparing activity start and finish dates, activity durations, and relative sequences of the activities can identify causes of each variance to a work activity. The complexity of this assessment generally depends on the nature and complexity of both the project and the issues being evaluated. The graphic below illustrates a more detailed and informative as-planned versus as-built schedule methodology:

The selection of a particular schedule analysis method should first be based on what schedule and work progress information is available and what format it is available in. The as-planned versus as-built schedule analysis methodology utilizes the most reliable data available and can be used even when data is limited. However, several considerations should be accounted for when choosing the appropriate schedule analysis methodology and the depth of the analysis, as each construction project is unique and has different contract requirements, situational variables, levels of documentation, and complexities. GlassRatner has addressed schedule delay issues on hundreds of construction-related matters, and its construction experts are skilled in preparing schedule delay analyses based on available data and client requirements.